- Home

- About

- Product Display

- Application field

- 技术服务

- News

- Company news

- Won the award of...

- We not only buil...

- 2019 Company Ann...

- Christmas Blessi...

- 巴基斯坦籍员工庆生活动

- Peentech won the...

- 2018年“威派格”杯外冈镇绿色...

- 公司新网站国庆节正式上线

- 浓浓中秋情

- 2018年篮球 “商会杯”

- 2018年吉他培训班圆满落幕

- 欢乐端午 浓情粽香

- The 24th Southea...

- The 16th China I...

- The 18th Western...

- 2017年度最具价值员工(MVP...

- 女神节,PEENTECH祝愿公司...

- The company comp...

- Peentech's ...

- 2017年上海恩太第四届“员工家...

- After sales news

- SAIC Motors-Main...

- Changshu AAM-Mod...

- Jiangsu Pacific ...

- SAGW-story of tr...

- ZF (Tianjin) Win...

- Valeo-A crawler ...

- BYD-The story of...

- 苏州米巴-粉末冶金齿套抛丸机大修...

- 双环集团- 第14台齿轮强化喷丸...

- 吉利汽车-周产1万套DCT7变速...

- 上海商用飞机-旋转喷枪组件完成调...

- 大连大众变速器-德国进口设备改造...

- 南京法雷奥-除尘器及丸料分离系统...

- PEENTECH为美国进口的螺伞...

- 双环桐乡工厂- peentech...

- PEENTECH成功改造钢丸分离...

- 中船集团验收连杆机器人喷丸机设备...

- 美国进口连杆抛丸机抛头升级改造项...

- 抛丸机的现代化升级输出效率同比提...

- 一汽大众-强化抛丸机搬迁及维修保...

- Training news

- Company news

- Contact Us

Application field

APPLICATION FIELDApplication of shot peening in wind power gears

1. Why wind power gears need shot peening?

China has advantages in geographical and climatic conditions, where has vigorously developed wind power in recent years as a clean renewable energy source. Although it started late comapred with other countries, however, the installed wind power capacity of China ranks the third in the world now, behinding the United Kingdom and Germany. Furthermore, the common height of wind turbines reaches 120 meters, the volume and weight of components are large, leading to the fact that the costs of maintenance and repair are a great concern. Therefore, the operating life of the wind power gearbox needs to be guaranteed.

After the heat treatment of wind power gears, there left the oxidized layer on the surface. Before the finished product, the oxidazation layer needs to be completely cleaned to ensure the adhesion of the subsequent painting. To improve the fatigue life of wind power gears, the shot peening process has also been gradually introduced around the world. In addition to the removal of the oxidized layer, the surface is also further strengthened, and the residual compressive stress is introduced leading to an improved fatigue life.

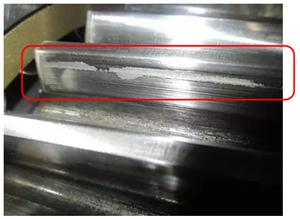

2.Where are the failure positions of wind power gears?

Wind turbine gear failure positions:

a)Wheel body (rarely occurs)-fracture-structure

b)Tooth surface-pitting /scuffing-contact fatigue

3、Commonly used wind power gear shot peening process

3.1Oxide layer removal via shot blasting

a)Cleanup level:Sa2.5)

b)Recommended shot: S390 / HRC44-52

c)Shot blasting position: whole gear

3.2 Sandblasting of tooth surface-improve surface roughness

a)Cleanup level:Sa2.5

b)Recommended shot: Glass shot/ B40

d)Shot blasting position: Tooth root of gear

3.3Tooth surface strengthening (enable to be treated together with oxide layer cleaning)

a)shot intensity:0.38-0.46mmA

b)coverage(Test piece saturation method):200%

c)surface roughness:≤Ra2.0 μm

d)Recommended shot: CW41 (1.0mm)/HV640 /G2

e)Shot peening position: Tooth root of gear

f)residual stress:There must be a point exceeding 1000 Mpa between 50-100 μm (normal direction of tooth root 30 ° tangent)

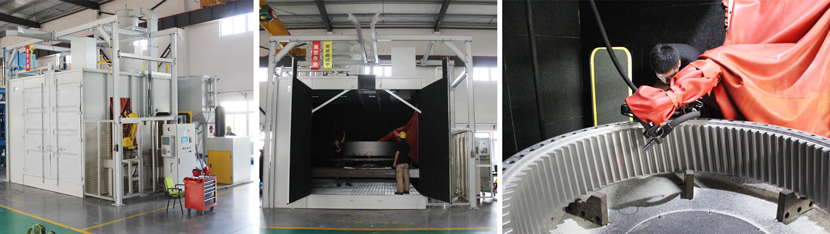

4. Shot blasting machines for wind power gears

4.1 Strengthening of tooth surface of wind power gear (considering cleaning function)

Recommended equipment: OH1717-P380 / 3/15

Hanging shot blasting machine

4.2 Sandblasting of gear tooth surface of wind power

Recommended equipment: MT25-G80II / 1 / R

Large rotary table sandblasting machine

沪公网安备 31011402005501号

沪公网安备 31011402005501号